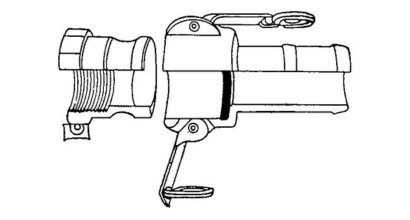

Cam & Groove Couplings

Accepted as an international standard. These are precision cast for excellent metallurgy. This coupling

gives fastest & simplest tight connection. The seal will remain tight because wear is reduced to a

minimum, this is because the gasket which is compressed is stationery, receives no friction & will

not become worn or buckled. It is recessed & will never fall out.

The principle behind the design of cam lock coupling is simple. Cam arms fitted on pivot pins gets

locked in the adopter groove, so that when the line pressure attempts to force the cam lock coupler and

adopter apart, the bottom edge of the adapter groove pushes with a equal pressure against the under

edge of the cam arm increasing the locking action. All the couplings pass through a hydrostatic test of

minimum 500 psi ( 35kg/cm2 ).

| Series | CG 6 |

|---|---|

| Size | 1/2” – 4” |

| Material | C.S, Aluminium, SS 304, SS 316 |

| Seals | Nitrile |

| Locking Mechanism | Cam Lock |

Fluids flows in either direction from coupler or adaptor

Features

- Fastest & simplest tight connection

- Interchangeability

- Positive locking & greatest resistance to vibration.

- Better flow characteristics

- No ball bearing, threading, twisting springs, snaps, tools, lugs, etc....

- Tightness under pressure

Operation

- Cam & groove couplings generally confirm to US military specifications, MILC-C-27487 and DIN 2828.

- This ensures interchangeability, quality & standardization of the product.

Applications

- For transfer of fluids, paints, oil , grease, water, slurries, chemicals etc...

- Oil Blending Platforms

- Pneumatic Conveyors.

- Process Industries

- Railways.

- TFire fighting Equipments.

- Steel plants.

Warning :

When using quick disconnect couplings, it is crucial to ensure that the media always flows from the coupler to the adapter for optimal performance and safety. Additionally, never attempt to connect or disconnect the coupler while it is under pressure, as this can lead to damage or hazardous fluid leaks. It is also important to avoid applying pulsative pressure to the coupler when it is disconnected, as this can compromise the integrity of the system and potentially cause malfunctions. Following these guidelines ensures safe and efficient operation of the coupling system.

For Best Performance:

Use only with recommended media.

Use only with the suggested operating temperature. n Be sure to choose the appropriate type of packing material for your application.

Keep the coupler clean and free of dust .

Use a filter for fluid and air as foreign material may damage the coupler.

Be sure that the thread tape scraps do not enter the line.

Do not over tighten fittings as the threads may be damaged.

Do not hit, bend, or pull. This may cause leakage or damage.

When using with a vibrating or impact device, install a 30 c.m. length of intermediate hose between the device & the coupler.

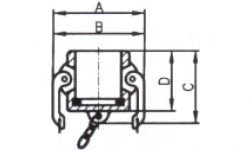

Cam & Groove Coupling- Dimensional Details

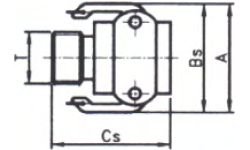

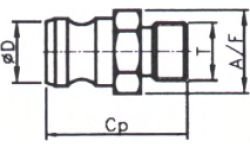

Male Coupler (B)

| SIZE | A | Bs | Cs |

|---|---|---|---|

| 1/2” | 117.0 | 60.0 | 52.8 |

| 3/4” | 117.0 | 60.0 | 52.8 |

| 1” | 133.0 | 69.0 | 63.5 |

| 11/2” | 186.0 | 87.0 | 82.5 |

| 2” | 195.0 | 97.0 | 85.7 |

| 21/2” | 236.3 | 114.3 | 88.9 |

| 3” | 255.0 | 137.0 | 91.6 |

| 4” | 280.0 | 162.0 | 101.6 |

| 5” | 305.0 | 190.0 | 101.0 |

| 6” | 413.0 | 260.0 | 123.0 |

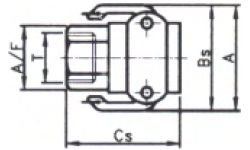

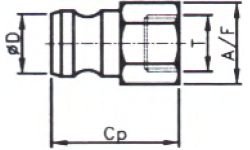

Female Coupler (D)

| SIZE | A | B | C | A/F |

|---|---|---|---|---|

| 1/2” | 117.0 | 60.0 | 55.0 | 32.0 |

| 3/4” | 117.0 | 60.0 | 55.0 | 32.0 |

| 1” | 133.0 | 69.0 | 63.0 | 40.0 |

| 11/2” | 186.0 | 87.0 | 71.8 | 55.0 |

| 2” | 195.0 | 97.0 | 84.5 | 70.0 |

| 21/2” | 236.3 | 114.3 | 88.9 | 82.0 |

| 3” | 255.0 | 137.0 | 91.6 | 101.5 |

| 4” | 280.0 | 162.0 | 93.0 | 130.0 |

| 5” | 305.0 | 190.0 | 100.0 | 150.0 |

| 6” | 413.0 | 260.0 | 121.5 | 182.0 |

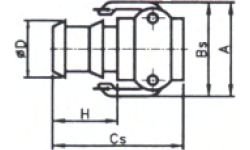

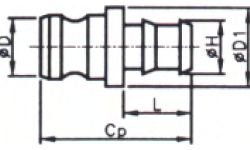

Hose Coupler (C)

| SIZE | A | Bs | Cs | H | OD |

|---|---|---|---|---|---|

| 1/2” | 117.0 | 60.0 | 78.0 | 38.0 | 15.0 |

| 3/4” | 117.0 | 60.0 | 90.0 | 50.0 | 21.0 |

| 1” | 133.0 | 69.0 | 106.0 | 57.1 | 27.5 |

| 11/2” | 186.0 | 87.0 | 116.8 | 70.0 | 39.5 |

| 2” | 195.0 | 97.0 | 133.5 | 73.0 | 53.0 |

| 21/2” | 236.3 | 114.3 | 136.5 | 79.4 | 65.5 |

| 3” | 255.0 | 137.0 | 174.5 | 100.0 | 78.1 |

| 4” | 280.0 | 162.0 | 167.8 | 107.8 | 103.0 |

| 5” | 305.0 | 190.0 | 207.0 | 127.8 | 130.5 |

| 6” | 413.0 | 260.0 | 216.0 | 146.0 | 156.5 |

Male Adaptor (F)

| SIZE | A/F | Cp | OD |

|---|---|---|---|

| 1/2” | 36.0 | 58.8 | 32.5 |

| 3/4” | 36.0 | 58.8 | 32.5 |

| 1” | 40.0 | 68.2 | 36.55 |

| 11/2” | 55.0 | 81.0 | 53.35 |

| 2” | 70.0 | 90.5 | 63.1 |

| 21/2” | 82.0 | 101.6 | 76.2 |

| 3” | 101.5 | 103.2 | 92.0 |

| 4” | 130.0 | 119.1 | 119.4 |

| 5” | 150.0 | 126.0 | 146.0 |

| 6” | 182.0 | 144.0 | 176.2 |

Female Adaptor (A)

| SIZE | A/F | Cp | OD |

|---|---|---|---|

| 1/2” | 36.0 | 41.3 | 32.5 |

| 3/4” | 36.0 | 41.3 | 32.5 |

| 1” | 40.0 | 46.5 | 36.55 |

| 11/2” | 55.0 | 57.4 | 53.35 |

| 2” | 70.0 | 66.0 | 63.1 |

| 21/2” | 82.0 | 70.5 | 76.2 |

| 3” | 101.5 | 71.44 | 92.0 |

| 4” | 130.0 | 80.0 | 119.4 |

| 5” | 150.0 | 86.0 | 146.0 |

| 6” | 182.0 | 94.0 | 176.2 |

Hose Adaptor (E)

| SIZE | OD1 | Cp | OH | OD | L |

|---|---|---|---|---|---|

| 1/2” | 36.0 | 76.8 | 15.0 | 32.5 | 38.0 |

| 3/4” | 36.0 | 82.3 | 21.0 | 32.5 | 50.0 |

| 1” | 37.8 | 94.6 | 27.5 | 36.55 | 57.1 |

| 11/2” | 56.0 | 106.9 | 39.5 | 53.35 | 60.3 |

| 2” | 73.0 | 130.2 | 53.0 | 63.1 | 73.0 |

| 21/2” | 85.7 | 142.9 | 65.5 | 76.2 | 63.5 |

| 3” | 101.5 | 165.1 | 78.1 | 92.0 | 100.0 |

| 4” | 133.4 | 177.8 | 103.0 | 119.4 | 107.8 |

| 5” | 160.0 | 190.0 | 130.5 | 146.0 | 127.8 |

| 6” | 187.0 | 225.0 | 156.5 | 176.2 | 146.0 |

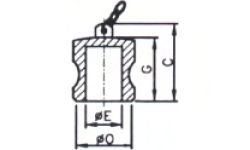

Dust Plug (DP)

| SIZE | 1/2 | 3/4 | 1 | 11/2 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|---|---|---|

| C | 37 | 37 | 42 | 51 | 60 | 64 | 66 | 67 | 68 |

| E | 14 | 19 | 24 | 36 | 45 | 71 | 80 | 86 | 86 |

| G | 29 | 29 | 32 | 41 | 49 | 53 | 53 | 54 | 54 |

| O | 32.6 | 32.6 | 36.5 | 53.3 | 63.0 | 92.0 | 119.4 | 146.0 | 176.0 |

Dust Cap (DC)

| SIZE | 1/2 | 3/4 | 1 | 11/2 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|---|---|---|

| A | 117 | 117 | 135 | 149 | 159 | 253 | 278 | 305 | 413 |

| B | 60 | 60 | 69 | 87 | 97 | 137 | 162 | 189 | 260 |

| C | 46 | 46 | 51 | 57 | 65 | 70 | 74 | 75 | 85 |

| D | 38 | 38 | 41 | 47 | 54 | 59 | 61 | 62 | 71 |