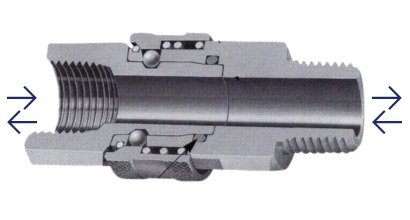

Straight Thru Couplings

They are designed without any valves to provide least resistance to fluid flow.

Therefore they require manual shut off valves in both if fluid loss is to be

prevented, when the coupling is disconnected.

The wide range of sizes from 1/8″ to 3″ allows the employment in fields

ranging from instrumentation to steel mills.

Unrestricted bore of the coupling provides / permits full flow of fluids. These

couplings can handle viscous liquids, chemicals.

| Series | ST-10 |

|---|---|

| Size | 1/4” – 3” |

| Material | C.S, Brass, SS 304, SS 316 |

| Seals | Nitrile |

| Locking Mechanism | Ball Lock |

| End Fittings | BSP Female Threads, BSP Male Threads, Hose Shank |

Fluids flows in either direction from coupler or adaptor

Features :

Suitable for viscous fluids ( such as grease )

Through type coupling ( valveless ) construction greatly reduces pressure loss & enables high flow rates.

Available in various standard body materials, sizes & end fittings, types to cope with a wide variety of applications and conditions.

Applications:

General fluid service

Hydraulic piping

Viscous

Air Compressed air, Gases, fluids, paints, oils, greases, powder, water and slurries.

Operation:

To connect pull back the locking sleeve and push adapter into the coupler.

Release the sleeve and the coupler will lock into the adapter.

To disconnect pull the sleeve back and remove the adapter.

For Best Performance:

Use only with recommended media.

Use only with the suggested operating temperature.

Be sure to choose the appropriate type of packing material for your application.

Keep the coupler clean and free of dust .

Use a filter for fluid and air as foreign material may damage the coupler.

Be sure that the thread tape scraps do not enter the line.

Do not over tighten fittings as the threads may be damaged.

Do not hit, bend, or pull. This may cause leakage or damage.

When using with a vibrating or impact device, install a 30 c.m. length of intermediate hose between the device & the coupler.

Warning :

For safe and effective use of quick disconnect couplings, always ensure that media flows from the coupler to the adapter. Never connect or disconnect the coupler while it is pressurized, as doing so can cause leaks or damage to the system. Additionally, avoid applying pulsative pressure to the coupler when it is disconnected, as this may compromise system integrity. Following these precautions ensures reliable operation and prolongs the life of the coupling equipment.

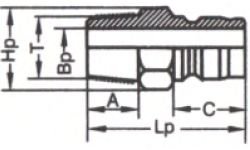

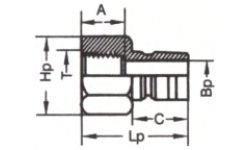

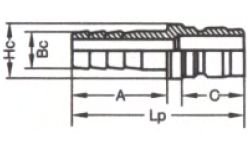

Straight Thru Couplings- Dimensional Details

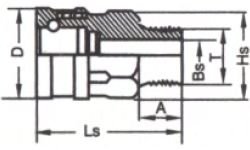

Male Coupler (B)

| Size | LS | Dø | HS | A | Bsø |

|---|---|---|---|---|---|

| 1/4” | 42 | 24 | 6Hex 22 x 24.2 | 13 | 7 |

| 3/8” | 46 | 28 | 6Hex 14 x 16.2 | 13 | 10 |

| 1/2” | 52 | 35 | 6Hex 22 x 24.2 | 17 | 13 |

| 3/4” | 57 | 40 | 6Hex 32 x 34.2 | 19 | 18 |

| 1-11” | 66 | 54 | 54øx2Hexx47 | 22 | 24 |

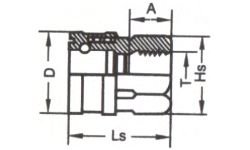

Female Coupler (D)

| Size | LS | Dø | HS | A |

|---|---|---|---|---|

| 1/4” | 32 | 24 | 6Hex 22 x 24.2 | 13 |

| 3/8” | 35 | 28 | 6Hex 14 x 16.2 | 13 |

| 1/2” | 45 | 35 | 6Hex 22 x 24.2 | 17 |

| 3/4” | 45 | 40 | 6Hex 32 x 34.2 | 19 |

| 1-11” | 49 | 54 | 6Hex 36 x 40 | 22 |

Hose Coupler (C)

| LP | DØ | Hpø | A | Tø | Bsø |

|---|---|---|---|---|---|

| 40 | 17 | 17 | 20 | 6.5 | 3 |

| 59 | 24 | 24 | 30 | 8 | 5 |

| 64 | 28 | 25 | 34 | 11 | 7 |

| 75 | 35 | 32 | 39 | 15 | 10 |

| 86 | 40 | 40 | 48 | 21 | 15 |

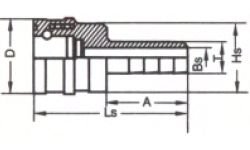

Male Adaptor (F)

| Size | Lp | C | HP | A | Bpø |

|---|---|---|---|---|---|

| 1/4” | 38 | 18 | 6Hex 14 x 16.2 | 13 | 6.5 |

| 3/8” | 43 | 21 | 6Hex 14 x 16.2 | 13 | 10 |

| 1/2” | 49 | 25 | 6Hex 22 x 24.2 | 17 | 13 |

| 3/4” | 53 | 23 | 6Hex 32 x 37 | 19 | 17 |

| 1-11” | 56 | 22 | 6Hex 36 x 40 | 22 | 24 |

Female Adaptor (A)

| Size | Lp | C | HP | A | Bpø |

|---|---|---|---|---|---|

| 1/4” | 34 | 18 | 6Hex 17 x 19.6 | 13 | 6.5 |

| 3/8” | 38 | 21 | 6Hex 21 x 24.2 | 13 | 10 |

| 1/2” | 45 | 25 | 6Hex 29 x 33.5 | 17 | 13 |

| 3/4” | 44 | 23 | |||

| 1-11” | 47 | 22 | 44øx 2Hex 40 | 22 | 26 |

Hose Adaptor (E)

| LP | C | Hpø | A | Tø | Bsø |

|---|---|---|---|---|---|

| 53 | 18 | 14 | 29 | 8 | 5 |

| 57 | 17 | 18 | 34 | 11 | 7 |

| 84 | 23 | 23 | 48 | 21 | 15 |

| 72 | 25 | 22 | 39 | 15 | 10 |

| 94 | 22 | 42 | 57 | 27 | 19 |